Table of Contents

LSR has taken a very crucial place in today’s industries. It is also gaining popularity as the most preferred solution in coating uses and demands because of the superior qualities it possesses. These coatings are very durable and have the capability of withstanding a good deal of impact force. It is also chemically resistant and can adequately handle extreme temperatures.

For this reason, LSR coating has versatile properties that can be suitable for use in different industries, which include automotive, electronics, and medicine, among others. This guide is all the help you’ll ever need if you wish to know where to buy liquid silicone rubber coatings. We will tell you about the various options that are available and what you should think about before you make a purchase.

Understanding Liquid Silicone Rubber Coatings

From industrial to commercial applications, LSR coatings are ideal because of their unique properties. These coatings are made from a two-component elastomer system that is combined and heat cured to get the final result. This curing process is what gives the coatings their special and highly desirable features.

The quick curing ability of the coating creates a protective layer that can handle most harsh environments. A proper understanding of the special properties of liquid silicone rubber coatings enables one to get the right type of coatings for the job. This results in the coating lasting for a longer period while at the same time delivering the maximum performance.

Why You Should Consider Using LSR Coating

It is important to know that liquid silicone rubber coatings have several advantages that make them unique. These coatings have the ability to tackle challenges that would be fatal to most materials, be it in terms of heat or cold resistance, flexibility, or chemical resistance.

Having knowledge of these advantages will enable one to appreciate why LSR coatings are popular and frequently used in industries and trade sub-sectors. Let’s explore the main benefits that make liquid silicone rubber coatings the best at increasing the durability and longevity of any application they are used in:

- Temperature Resistance: LSR coatings can withstand high and low temperatures without taking on any serious damages. The possible temperature range for these coatings is from -60 to 200 degrees Celsius. This makes them ideal to use in areas that are characterized by high heat or extremely low temperatures.

- Chemical Resistance: Chemical resistance is another related property of the coatings, which are capable of withstanding almost all types of chemical substances, such as oil as well as solvents. They are equally able to shield what they are coating from erosion and long-term deterioration. This is why LSR coatings are mostly applied in industries where the equipment is exposed to chemicals most of the time.

- Durability: Liquid silicone rubber coatings are highly durable under most stressful conditions. They can effectively counter any mechanical stress, UV light, or water damage. Anything you put these coatings on will have strong and long-lasting protection in any environment.

- Flexibility: The unique properties of liquid silicone rubber allow it to stretch extensively and return to its original shape. This flexibility makes these coatings ideal to use as seals in automotive and manufacturing industries.

- Biocompatibility: Materials with biocompatibility are crucial for medical applications. This property means that LSR coatings will not have an adverse reaction with any part of the human body. This makes it safe to use in medical devices such as implants that are in contact with your body for a very long period of time. Biocompatibility makes these coatings appropriate for use in the production of items used in households, such as the utensils that are used in the kitchen.

Where to Buy Liquid Silicone Rubber Coatings

Liquid silicone rubber (LSR) coatings are in great demand because of their versatile characteristics. These attributes make them useful in different fields ranging from electronics, automobiles, health, and construction, among others. There are several avenues to explore if you want to buy LSR coatings. This section will help you understand how to buy liquid silicone rubber coatings so that they can meet the requirements of your application.

Contract Manufacturing Organizations

For your project’s complex parts where you have to apply the LSR coatings differently, you can consider outsourcing with CMOs. These organizations specialize in applying LSR coatings to different materials and make sure that the coating meets the required standard. As such, CMOs are ideal for companies that require outsourcing of the coating process to enable them to concentrate on other core business areas.

Electronic Supply Stores

For those in the electronics industry, liquid silicone rubber is preferred as the material that electronics components are coated with. Such suppliers always have coatings that are specifically designed for electronic applications, for example, coatings for PCBs or connectors. With the help of such a supplier having prior knowledge about the electronics industry as well as LSR coatings, you can obtain products that fit the criteria of your application.

Local Coating Facilities

Some regions have specialized coating facilities where a large variety of LSR coating jobs are offered. Such establishments have all the tools and personnel required in the application of LSR coatings on various materials, such as metal or plastic. Using a local facility can also be beneficial where you need short delivery times or you prefer to be heavily involved in the process of coating.

Trade Shows

Another way to find the right LSR coatings is through trade shows and industry-related conferences, since such events provide ideal exhibition platforms. Such fairs give you the chance to understand the entire range of products and specific formulations available in the market. Visitors have the opportunity to learn about the highest quality options as well as new innovations that aren’t available on the market yet.

Automotive Parts Suppliers

The automotive industry needs materials with a certain level of ruggedness and durability. This is where liquid silicone rubber coatings come in. Some of the automotive parts suppliers, especially those involved in the manufacturing of seals and gaskets, have developed LSR coatings suitable for use in automobiles. Coatings for automotive appliances are generally developed for high temperature and fuel resistance. Therefore, they are preferably used in the engine and other crucial automotive parts.

Insilicone: A Leading Supplier for LSR Products

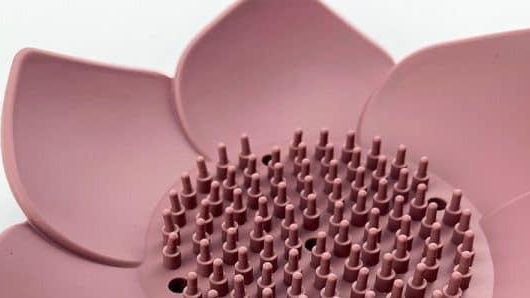

Insilicone is an industry leader when it comes to providing high-quality and reliable liquid silicone rubber products. They have a large variety of items, from baby products and kitchenware to phone cases. These quality products are available to you from the comfort of your home. Therefore, you have easy access to durable LSR products, especially for parents looking for the best baby products. You can also get stylish yet robust phone cases that will last you a long time. Their products have designs for everyday use along with options suited for more special occasions.

Conclusion

I think deciding on which liquid silicone rubber coating to use goes beyond simply choosing a product; you need to know the specifications of your application. You can start by focusing on the sources’ expertise and what they have to offer. CMOs can apply special coatings according to your requirements, while the electronic supply stores give you options ideal for delicate components. On-site coating facilities provide on-the-go services to meet urgent demands, while trade shows give an insight into the latest technologies. Thus, by choosing the right source for your coating needs, you ensure that the application lasts a long time with the best and most reliable performance.